Fasteners and Machining: Integrating Accuracy and Strength in Production

Fasteners and Machining: Integrating Accuracy and Strength in Production

Blog Article

Navigating the World of Fasteners and Machining: Approaches for Accuracy and Speed

In the detailed world of bolts and machining, the mission for accuracy and rate is a perpetual obstacle that requires meticulous attention to information and calculated planning. From understanding the varied range of bolt types to selecting optimum materials that can stand up to extensive needs, each action in the process plays a critical function in accomplishing the wanted end result.

Understanding Fastener Types

When picking bolts for a task, comprehending the different types offered is crucial for ensuring optimal efficiency and reliability. Bolts are made use of with nuts to hold materials together, while screws are flexible bolts that can be utilized with or without a nut, depending on the application. Washers are essential for dispersing the load of the fastener and stopping damage to the product being attached.

Selecting the Right Materials

Understanding the significance of picking the right materials is critical in making sure the ideal efficiency and integrity of the picked bolt kinds reviewed formerly. When it concerns fasteners and machining applications, the product option plays an important role in determining the total stamina, resilience, rust resistance, and compatibility with the intended environment. Various products use differing residential or commercial properties that can substantially impact the efficiency of the fasteners.

Typical products utilized for bolts include steel, stainless-steel, titanium, brass, and aluminum, each having its one-of-a-kind strengths and weaknesses. Steel is renowned for its high toughness and resilience, making it ideal for a wide variety of applications. Stainless-steel supplies excellent rust resistance, suitable for environments prone to moisture and chemicals. Aluminum is light-weight and corrosion-resistant, making it appropriate for applications where weight decrease is crucial. Brass is frequently selected for its visual appeal and outstanding conductivity. Titanium is known for its extraordinary strength-to-weight ratio, making it perfect for high-performance applications. Selecting the right product involves considering variables such as toughness requirements, ecological problems, and budget restrictions to make sure the desired performance and long life of the fasteners.

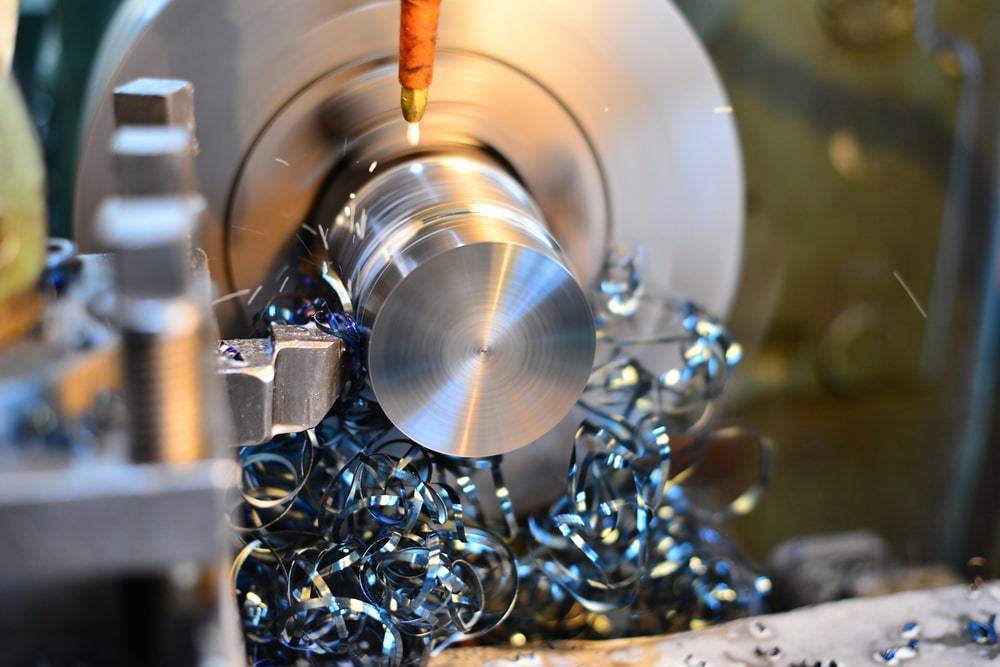

Precision Machining Techniques

In enhancement to CNC machining, various other accuracy strategies like grinding, transforming, milling, and exploration play important functions in fastener production. Grinding aids achieve fine surface area finishes and tight dimensional resistances, while transforming is typically made use of to develop cylindrical components with specific diameters. Milling and exploration procedures are crucial for shaping and developing holes in fasteners, ensuring they satisfy i thought about this exact specifications and function properly.

Enhancing Rate and Efficiency

To maximize fastener production procedures, it is important to improve procedures and execute effective methods that complement precision machining techniques. One crucial approach for improving speed and efficiency is the implementation of lean production principles. By lowering waste and concentrating on continual enhancement, lean methods aid get rid of bottlenecks and enhance workflow. In addition, purchasing automation innovations can considerably increase manufacturing rate. Automated systems can deal with repeated tasks with precision and rate, enabling employees to concentrate on more complex and value-added tasks. Embracing Just-In-Time (JIT) supply monitoring can additionally boost performance by making certain that the ideal materials are offered at the correct time, decreasing excess supply and reducing lead times. In addition, cultivating a culture of collaboration and interaction among staff member can improve overall performance by advertising openness, problem-solving, and innovation. By incorporating these methods, suppliers can accomplish a balance in between speed and accuracy, eventually improving their one-upmanship in the fastener industry.

Quality Control Procedures

Carrying out rigorous top quality control actions is vital in ensuring the dependability and consistency of fastener items in the production procedure. Quality control steps incorporate different stages, beginning from the option of raw products to the last examination of the completed bolts. One fundamental facet of high quality control is performing comprehensive product evaluations to verify conformity with specs. This includes assessing factors such as product composition, stamina, and sturdiness to guarantee that the bolts meet industry standards. Furthermore, checking the machining refines is vital to copyright dimensional precision and surface finish top quality. Making use of innovative modern technology, such as automatic evaluation systems and accuracy measuring tools, can improve the accuracy and efficiency of quality assurance procedures.

Routine calibration of devices and machinery is critical to keep try this uniformity in production and make sure that bolts satisfy the needed resistances. Executing rigorous protocols for identifying and attending to non-conformities or flaws is my site vital in stopping substandard products from going into the marketplace. By establishing an extensive quality control framework, suppliers can maintain the track record of their brand name and provide bolts that meet the greatest criteria of efficiency and toughness.

Conclusion

In the elaborate world of fasteners and machining, the quest for precision and rate is a continuous difficulty that requires careful interest to information and calculated planning. When it comes to fasteners and machining applications, the product option plays an essential role in figuring out the overall strength, longevity, rust resistance, and compatibility with the desired environment. Precision machining involves numerous innovative techniques that guarantee the tight resistances and requirements needed for bolts.In addition to CNC machining, other accuracy strategies like grinding, turning, milling, and exploration play vital duties in fastener manufacturing.To maximize fastener production procedures, it is vital to improve operations and execute efficient methods that enhance accuracy machining methods.

Report this page